U-type dehumidifying heat pipe heat exchanger

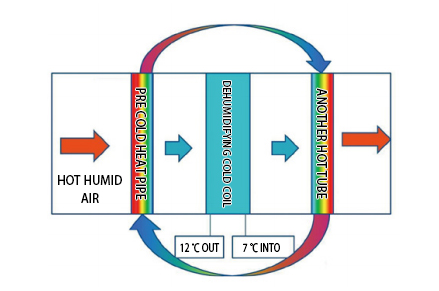

The energy saving dehumidification heat pipe is composed of precooling and reheating parts. The two parts are connected together without providing energy. Relying on the middle dehumidification cooling coil, it realizes the precooling and reheating of air, thus achieving the purpose of energy saving dehumidification.

Firstly, the hot and humid air is pre-cooled through the cold side of the heat pipe. The hot and humid air transfers heat with the heat pipe. The heat pipe medium absorbs heat from the air. The wet air cooled by the heat pipe enters the cold coil, and the moisture in the air is cooled to reach saturation and then condenses, thus achieving the purpose of dehumidification.

After passing through the cold coil, the air enters into the reheat tube to transfer heat with the heat pipe. The low-temperature air absorbs heat, the temperature rises, and the relative humidity decreases. The medium in the heat pipe releases heat, condenses from the gaseous state to the liquid state, and flows back into the heat absorption zone along the wall of the pipe.

Structural features

· Realize energy recovery, saving up to 30% of energy compared with traditional refrigeration dehumidification;

· Reduce refrigerating capacity and energy consumption of refrigerating machine;

· Reheat after supercooling to save reheat;

· No operating parts, no spare parts, no maintenance costs;

Application

· Industrial and commercial dehumidification systems

· Process air conditioning dehumidification system

· Dehumidification system for medical and electronic industry

· Dehumidification system of drying equipment