Indirect Evaporative Cooling Air-conditioning System

With the advent of the 5G big data era, network evolution and the rapid development of the data industry, the scale of large data centers(DC) is getting larger and larger, and the power consumption of data centers is also increasing. According to statistics, the national DC electricity consumption in 2018 was 160.889 billion kW/h, surpassing Shanghai's total electricity consumption in 2018, accounting for 2.35% of China's total electricity consumption. Moreover, It is expected to reach 266.792 billion kW/h in 2023, The average annual growth rate will reach 10.64%, which is approximately equal to the power generation capacity of 2.5 Three Gorges.

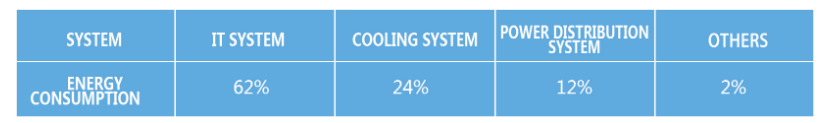

More importantly, power consumption has become a bottleneck restricting the development of data center services. The following table shows the proportion of energy consumption of each system configuration in the data center. From the analysis of the data in the table, it can be found that in the non-IT energy consumption, about 63% of the loss is caused by the data center cooling system.

In response to the high energy consumption of the data center cooling system, various energy-saving solutions have been tried in the industry. At the result, Indirect Evaporative (IEC) is one of the most promising cooling solutions.

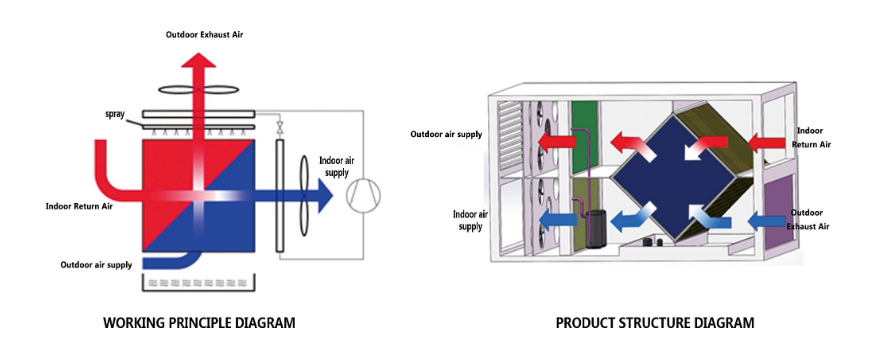

The following figure shows the working principle diagram and product structure diagram of indirect evaporative cooling system.

The indirect evaporative cooling system mainly includes three core components: plate heat exchanger, spray system, and compressor supplementary cooling system. During the cooling process, the air to be treated inside the data center passes through the air heat exchange device. Firstly, the outdoor air is used to cool the closed indoor air. At the same time, the spray system spray water uses the heat of the outdoor air to evaporate in the plate heat exchange device. Absorb heat to reduce the temperature of the air to be processed. As the result, making cool the circulating air inside the DC to the greatest extent. Throughout the process, indoor air is a closed loop system, while outdoor air is an open system. Outdoor air does not allow enter the DC, thus preventing moisture and pollutants in the outdoor air from entering the DC. Since the treated air does not directly contact with water, its moisture content remains unchanged, realizing isohumid cooling of air.

Operating mode

Depending on the outdoor temperature, the Evaporative Cooling Air-conditioning can adopt three operating modes.

Taking a single set of system (selecting BXB2000-2200-12.0 plate heat exchanger) as an example, the selection calculation shows that compared to a pure refrigeration and air-conditioning system, adopting an indirect evaporative cooling system. The air sensible plate heat exchanger can recover 194kw per hour. Spray system can absorb 686kw of heat, and recover a total of 880kw of heat. It can be seen that the use of an indirect evaporative cooling system can save 352kw*h of electricity per hour for the evaporative cooling system, and the energy saving effect is significant.

Case show