Industrial thermal emission heat recovery & reuse system

There are many drying equipment is often used to raise the air (fresh air) to a certain temperature and process the materials. Such as, food, chemical, pharmaceutical, electronics, spraying, printing, paper, chemical fiber and other industries. However, the used air is discharged as exhaust gas (exhaust air), and the exhaust gas is usually high in temperature and directly discharged into the atmosphere, which will cause a lot of energy waste.

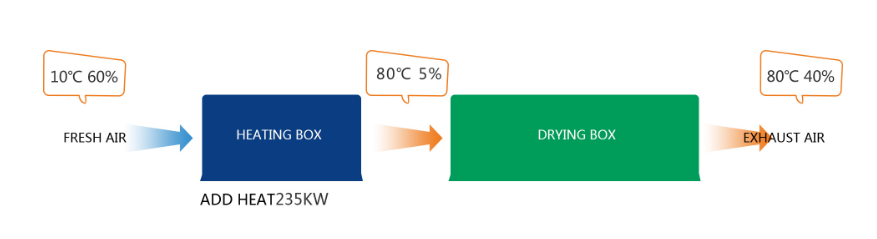

Drying case

For example, assuming a place with an annual average temperature of 10°C, a drying system air volume of 10000m3/h, and a drying process temperature of 80°C, it is necessary to provide about 235kW of heat to the drying box by means of electric or steam heating. The process is as follows, if the exhaust gas is directly discharged, the 235 kW of heat heated by electric or steam is will discharged into atmosphere, resulting in a waste of energy.

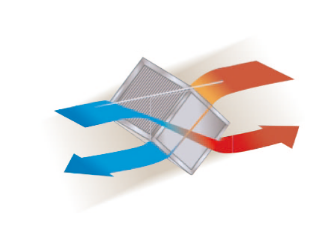

Schematic diagram of fresh air ventilation equipment with heat recovery

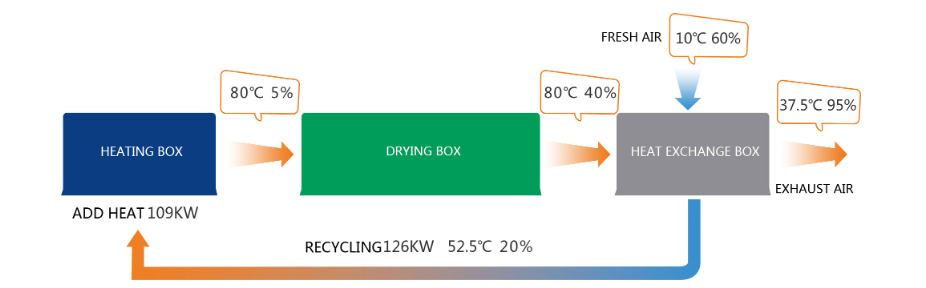

In the exhaust gas emission system, adding a heat exchange box that can realize the waste heat recovery.

The main component of the heat exchange box is the BXB plate heat exchanger. The plate heat exchanger is mainly made of aluminum foil (or stainless steel foil). When there is a temperature difference between two airflows that are isolated by aluminum foil and flow in opposite directions, heat transfer will occur to realize energy recovery. Through the BXB air sensible heat exchanger, the conversion in the exhaust air can be used to preheat the fresh air. As the result, it will achieve the purpose of energy saving.

Energy saving effect analysis

According to the previous example, use the heat in the exhaust air to preheat the fresh air from heat exchange box. The fresh air temperature increased from 10℃ to 52.5℃, and the heat input from the heating box is reduced from 235kW to 109kW, which saves 126kW of heat and reduces the amount of electricity or steam consumed for fresh air heating. The process is as follows: